Stay ahead of consumer demand and market disruptions with an integrated data strategy on a modern cloud data platform

March 16, 2022 | By Naresh Polali

When a consumer walks into a brick-and-mortar store, an empty shelf is the last thing retailers and consumer packaged goods (CPG) manufacturers want them to see. From in-store to online and mobile, consumers expect retailers to provide a wide range of product selection and predictable deliveries at the lowest price point. They want seamless, omnichannel experiences. Consumers clearly know what, when and where they want the product.

How do organizations meet this demand? Supply chain visibility. This visibility results from deep collaboration between retailers and CPG manufacturers powered by a modern cloud data platform, allowing them to quickly respond to market changes. Keep reading for how to create and improve supply chain visibility.

Increasing Complex, Uncertain Supply Chain

Keeping up with today’s savvy consumer relies heavily on joint efforts between retailers and CPG manufacturers. With the current global scenario, where most product crosses multiple borders, supply chain is becoming increasingly complex and uncertain. A typical CPG manufacturer must plan and orchestrate with tens of thousands of SKUs, orders and material movement between manufacturing plants, suppliers and distribution centers.

Therefore, the supply chain process must connect data that anticipates consumer needs and adjusts to disruptions to increase efficiency and gain the competitive advantage.

Here are four tips to optimize supply chain visibility:

1. Make it a demand-driven supply chain. Demand forecasting is a key function across all industries, helping companies determine accurate quantities of finished goods, raw materials, manufactured resources and items purchased. Demand-driven supply chains start with a demand triggered by a point of sale (POS) and true customer purchases.

The retail data cloud service of Snowflake, for example, provides a data library through its data share feature to integrate external data to provide data enhancement and AI/ML-driven planning processes. Organizations that use this service can then estimate sales based on the POS and adjust the supply network in real time to meet consumer needs. With the recent explosion of data from various internal, external and exogenous data sources, a true AI/ML-driven planning process can help predict accurate demand.

Benefits of a demand-driven supply chain:

- Top-line and bottom-line growth. Demand-driven planning boosts supply chain functions by combining a good mix of products and customers to meet customer demands. The results are cost reductions and increased sales generated from operational efficiencies.

- Inventory optimization. Putting the right product at the right inventory levels minimizes stock-outs and overstock situations, improving shelf vacancy and inventory turns.

- Competitive edge. CPG manufacturers know what products to use and can view their data faster than their competitors.

2. Use integrated supply chain analytics. Coupled with demand forecasting, a well-defined sales and operation planning process can cascade this down through the supply chain, including supply chain inventory management, manufacturing procurement, logistics and warehousing. A potential out-of-stock situation at the store can be due to a quality issue happening thousands of miles away at a supplier.

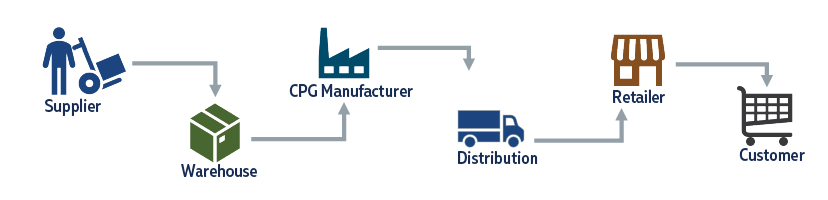

To be effective in the consumer-driven environment, companies should break down functional silos by connecting the flow and transform this into actionable intelligence. End-to-end integration of these functions provides deep visibility into the potential issues, and thereby helps retailers and CPG manufacturers respond proactively. Integrated supply chain analytics can help organizations track the flow of goods from supplier to manufacturer to distribution center and all the way to the retail store, providing a 360-degree view of the CPG product at any given point of time.

Key components of supply chain analytics:

- Supplier scorecards track key performance indicators to identify suitable vendors to partner with. They provide objectivity on whether a vendor can keep up with a set delivery cycle, quantities, timeliness and quality metrics.

- Distribution and logistics track the flow of goods from suppliers to customers, inventory levels at distribution channels, and improve inbound and outbound logistics performance.

- Inventory analytics show raw material and finished inventory at manufacturing warehouses, distribution centers and stores, AI/ML-based stock-out predictions and provide inventory optimization.

3. Drive data insights from various data sources. Supply chain systems are inherently complicated because different systems interact with each other to move products from one end of the network to the other. A good data strategy incorporating multiple data sources, however, can handle the three V’s: volume, velocity and veracity.

Types of data to enrich supply chain visibility:

- Internal data: Retail and CPG manufacturers use a variety of business applications to manage their business functions. Enterprise resource planning (ERP) applications, such as Oracle and SAP, manage inventory, procurement, logistics, supply planning and finance functions. Data can be used from manufacturing execution systems (MES), which manage manufacturing plant execution, warehouse management systems (WMS) and transportation management systems (TMS).

- Consumer data: While internal data mainly depends on multiple systems, like ERP, MES, WMS, TMS, etc., consumer data is quite diverse. Retailers provide daily/weekly POS, inventory, product and promotion activity data in their respective format. Online marketplace data providers, like Keepa, provide deep insight into consumer buying habits. CPG manufacturers also depend on syndicate data for market and competitive intelligence.

- Exogenous data: In an integrated supply chain environment, multiple external, economic and global factors play a critical role and have the potential to disrupt the whole supply chain.

Data from these types of sources should be cleansed, harmonized and combined. That way, information can be easily consumed by planning, sales, supply chains, promotions and inventory management teams. Organizations gain insight into end-to-end supply chains when they can observe the flow of materials. This allows them not only to react to changing consumer needs but also to predict possible interruptions and take initiative.

4. Prioritize collaboration and data sharing. While volumes of data are available to take actionable insight, deep collaboration in sharing this information between retail and CPG manufacturers plays a critical role in the overall success of enabling a consumer-driven supply chain. Traditionally, organizations are confined to storing the information within that ecosystem. With the emergence of public cloud, technology can help overcome these present-day challenges.

Optimize the Consumer Experience with Supply Chain Visibility

Help fix urgent issues in a timely manner

Identify possible disruptions and enable assertive problem-solving

Keep the focus on processes instead of functions

Create a shared environment to securely exchange data across companies

Streamline end-to-end supply chain practices and operations

In addition, retailers and CPG manufacturers can avoid inventory buildup and focus on demand sensing to enhance operational efficiencies by implementing AI/ML models. Companies can shrink the overall response time across functions, resulting in lower costs and rapid resolutions for consumer demands and logistics requirements.

Using these four tips, retailers and CPG manufacturers can win at the shelf and keep consumers coming back for more.

Learn more about our data analytics capabilities and our work with Snowflake.

Strategic Partnerships

Transformational technologies demand equally transformative partnerships. The world’s leading technology brands work with us because of our scale, speed and quality—building upon their foundation to foster and share ideas that help our clients grow. With TEKsystems by your side, you can reap the benefits of best-in-class implementation, integration and support—making the most of your technology investments and powering next-gen innovation.